As a professional in the construction industry, I have come across various types of screw anchors. Screw anchors are versatile fasteners that are used to secure different types of materials to different types of surfaces. They are essential in construction projects because they provide a reliable and secure point of attachment. In this comprehensive guide, I will demystify the different types of screw anchors to help you choose the right one for your project.

Table of Contents

Introduction to Screw Anchors

Screw anchors are fasteners that are designed to provide a strong and reliable point of attachment. They are used to secure materials to different surfaces, including concrete, brick, and drywall. Screw anchors come in different sizes and designs, each with its unique features and benefits.

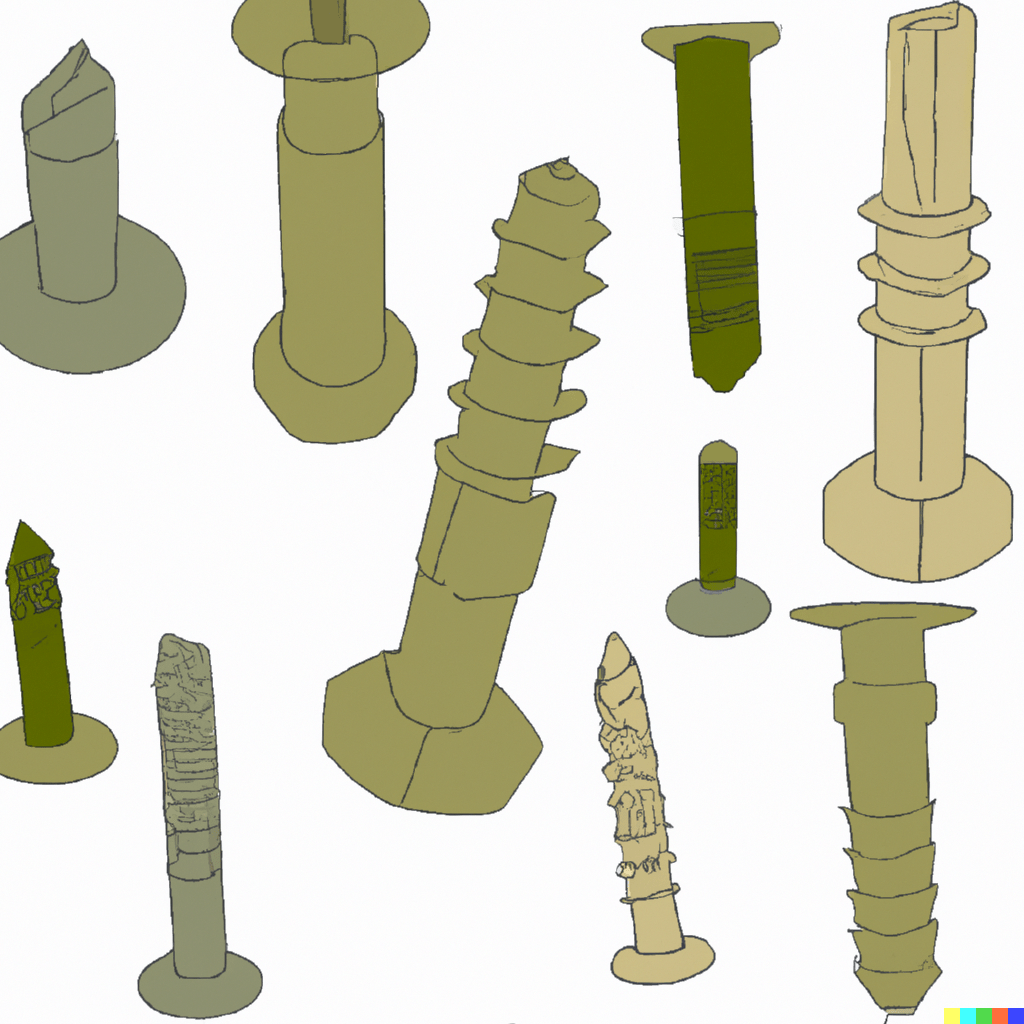

Understanding the Different Types of Screw Anchors

There are various types of screw anchors that you can use for your construction project. Some of the most common types include expanding screw anchors, threaded screw anchors, plastic screw anchors, wedge anchors, sleeve anchors, drop-in anchors, and concrete screw anchors.

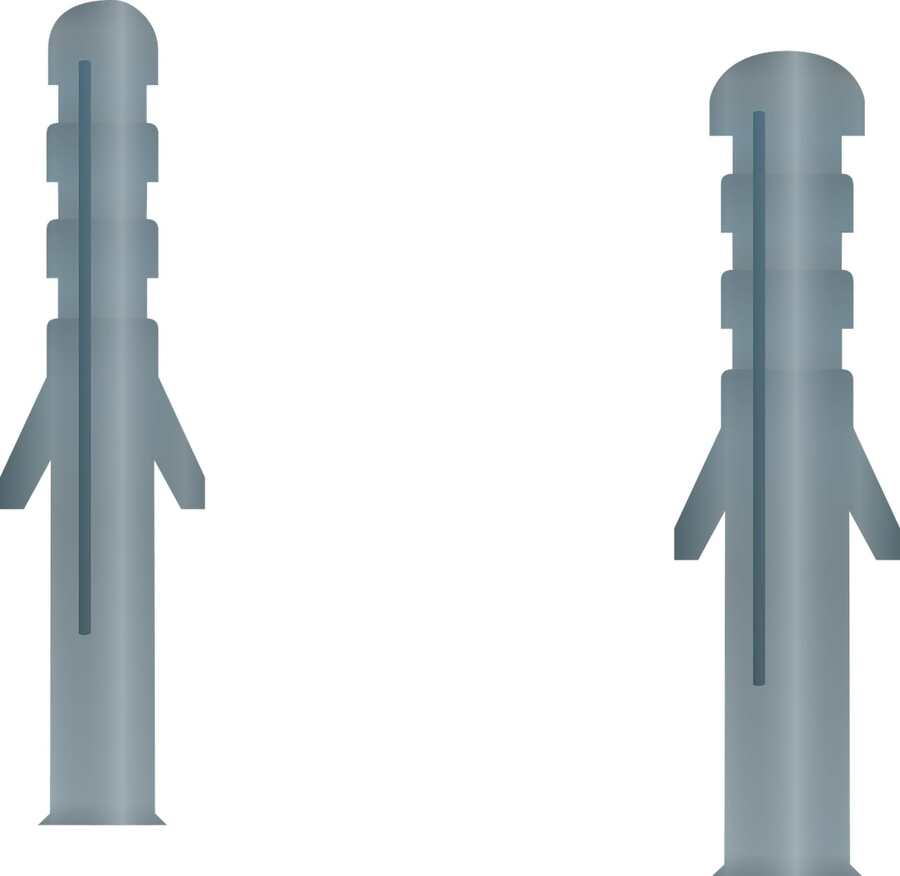

Expanding Screw Anchors

Expanding screw anchors are designed to expand and grip the surface of a material when a screw is inserted. They are commonly used to attach materials to concrete and are ideal for heavy-duty applications. Expanding screw anchors are available in different sizes and designs, including sleeve-type and wedge-type anchors.

Threaded Screw Anchors

Threaded screw anchors are designed to provide a strong and reliable point of attachment for materials. They are commonly used to attach materials to drywall and are ideal for light-duty applications. Threaded screw anchors are available in different sizes and designs, including plastic anchors and metal anchors.

Plastic Screw Anchors

Plastic screw anchors are ideal for light-duty applications and are commonly used to attach materials to drywall. They are designed to provide a strong and reliable point of attachment and are available in different sizes and designs.

Wedge Anchors

Wedge anchors are designed to provide a strong and reliable point of attachment for materials. They are commonly used to attach materials to concrete and are ideal for heavy-duty applications. Wedge anchors are available in different sizes and designs, including sleeve-type anchors and clip-type anchors.

Sleeve Anchors

Sleeve anchors are designed to provide a strong and reliable point of attachment for materials. They are commonly used to attach materials to concrete and are ideal for medium-duty applications. Sleeve anchors are available in different sizes and designs, including expansion-type anchors and compression-type anchors.

Drop-in Anchors

Drop-in anchors are designed to provide a strong and reliable point of attachment for materials. They are commonly used to attach materials to concrete and are ideal for heavy-duty applications. Drop-in anchors are available in different sizes and designs, including flush-mount anchors and countersunk anchors.

Concrete Screw Anchors

Concrete screw anchors are designed to provide a strong and reliable point of attachment for materials. They are commonly used to attach materials to concrete and are ideal for medium-duty applications. Concrete screw anchors are available in different sizes and designs, including hex-head anchors and flat-head anchors.

Choosing the Right Screw Anchor for Your Project

When choosing the right screw anchor for your project, there are various factors that you need to consider. Some of the most important factors include the type of material you are attaching, the type of surface you are attaching the material to, the weight of the material, and the location of the attachment point.

Factors to Consider When Selecting a Screw Anchor

There are various factors that you need to consider when selecting a screw anchor for your project. These factors include the type of material you are attaching, the type of surface you are attaching the material to, the weight of the material, and the location of the attachment point.

Type of Material You are Attaching

The type of material you are attaching is an essential factor to consider when selecting a screw anchor. Different materials have different properties, and you need to choose a screw anchor that is compatible with the material you are attaching. For example, if you are attaching wood to concrete, you may need to use a wedge anchor or a sleeve anchor.

Type of Surface You are Attaching the Material to

The type of surface you are attaching the material to is another essential factor to consider when selecting a screw anchor. Different surfaces require different types of screw anchors, and you need to choose a screw anchor that is compatible with the surface you are attaching the material to. For example, if you are attaching a material to drywall, you may need to use a threaded screw anchor or a plastic screw anchor.

Weight of the Material

The weight of the material is another essential factor to consider when selecting a screw anchor. Different screw anchors have different weight limits, and you need to choose a screw anchor that can support the weight of the material you are attaching. For example, if you are attaching a heavy object to concrete, you may need to use a drop-in anchor or a wedge anchor.

Location of the Attachment Point

The location of the attachment point is another essential factor to consider when selecting a screw anchor. Different screw anchors have different installation requirements, and you need to choose a screw anchor that is compatible with the location of the attachment point. For example, if the attachment point is in a tight space, you may need to use a sleeve anchor or a concrete screw anchor.

Installation Tips for Screw Anchors

Proper installation is essential for the performance and reliability of screw anchors. Here are some tips to help you install screw anchors correctly:

Prepare the Surface

Before installing the screw anchor, you need to prepare the surface by cleaning it and removing any debris. This will ensure that the screw anchor grips the surface properly and provides a reliable point of attachment.

Choose the Right Drill Bit

Choosing the right drill bit is essential for the proper installation of screw anchors. The drill bit size should match the size of the screw anchor to ensure that it fits snugly and securely.

Drill the Hole to the Correct Depth

Drilling the hole to the correct depth is essential for the proper installation of screw anchors. The depth of the hole should match the length of the screw anchor to ensure that it fits snugly and securely.

Insert the Screw Anchor

Inserting the screw anchor correctly is essential for the proper installation of screw anchors. The screw anchor should be inserted straight into the hole and should fit snugly and securely.

Tighten the Screw

Tightening the screw correctly is essential for the proper installation of screw anchors. The screw should be tightened until it is snug, but not over-tightened, as this can cause the screw anchor to lose its grip.

Common Mistakes to Avoid When Using Screw Anchors

There are various common mistakes that you need to avoid when using screw anchors. These mistakes can affect the performance and reliability of screw anchors and can lead to failures.

Over-Tightening the Screw

Over-tightening the screw can cause the screw anchor to lose its grip and can affect its performance and reliability. It is essential to tighten the screw until it is snug, but not over-tightened.

Using the Wrong Size Screw Anchor

Using the wrong size screw anchor can affect its performance and reliability. It is essential to choose a screw anchor that is compatible with the size of the screw and the weight of the material you are attaching.

Failing to Prepare the Surface

Failing to prepare the surface can affect the grip of the screw anchor and can lead to failures. It is essential to clean the surface and remove any debris before installing the screw anchor.

Choosing the Wrong Type of Screw Anchor

Choosing the wrong type of screw anchor can affect its performance and reliability. It is essential to choose a screw anchor that is compatible with the material you are attaching, the surface you are attaching the material to, the weight of the material, and the location of the attachment point.

Best Practices for Screw Anchor Maintenance

Proper maintenance is essential for the performance and reliability of screw anchors. Here are some best practices to help you maintain your screw anchors:

Regular Inspection

Regular inspection is essential to ensure that your screw anchors are performing correctly. You should inspect your screw anchors regularly to check for any signs of wear or damage.

Cleaning

Cleaning your screw anchors regularly is essential to ensure that they perform correctly. You should clean your screw anchors regularly to remove any debris or dirt that may affect their performance.

Lubrication

Lubricating your screw anchors regularly is essential to ensure that they perform correctly. You should lubricate your screw anchors regularly to prevent corrosion and ensure that they remain functional.

Replacement

Replacing your screw anchors when they are worn or damaged is essential to ensure that they perform correctly. You should replace your screw anchors when they show signs of wear or damage to prevent failures.

Conclusion

In conclusion, screw anchors are versatile fasteners that are essential in construction projects. Understanding the different types of screw anchors and choosing the right one for your project is essential for their performance and reliability. By following the installation tips, avoiding common mistakes, and maintaining your screw anchors, you can ensure that they provide a strong and reliable point of attachment for your materials.

Disclaimer: This article is intended for informational purposes only and does not constitute professional advice. Always consult with a licensed contractor or construction professional for your specific needs.

1 Comment