In the realm of construction and DIY projects, screws play an indispensable role. While the fundamental act of driving a screw may seem elementary, mastering advanced screwdriving techniques can transform your work quality, efficiency, and safety. As you strive to refine your fastening skills, understanding these sophisticated methods is paramount.

Table of Contents

1. The Basics of Screwdriving

Before delving into advanced techniques, it’s vital to establish a solid foundation. A screwdriver’s primary function is to convert manual effort into torque, ensuring the screw is securely fastened. The critical aspects of basic screwdriving include:

- Selecting the right screwdriver: Ensure the screwdriver head matches the screw type.

- Applying pressure: Apply consistent pressure to prevent the tool from slipping out of the screw head.

- Turning the screwdriver: Turn the screwdriver clockwise for tightening and counter-clockwise for loosening.

2. Understanding Screw Types

The success of any screwdriving task lies in choosing the right screw. Familiarize yourself with common screw types such as Phillips, flathead, Torx, and Allen. Each screw type requires a specific screwdriver or bit, emphasizing the importance of tool and screw compatibility.

3. The Importance of the Right Tool

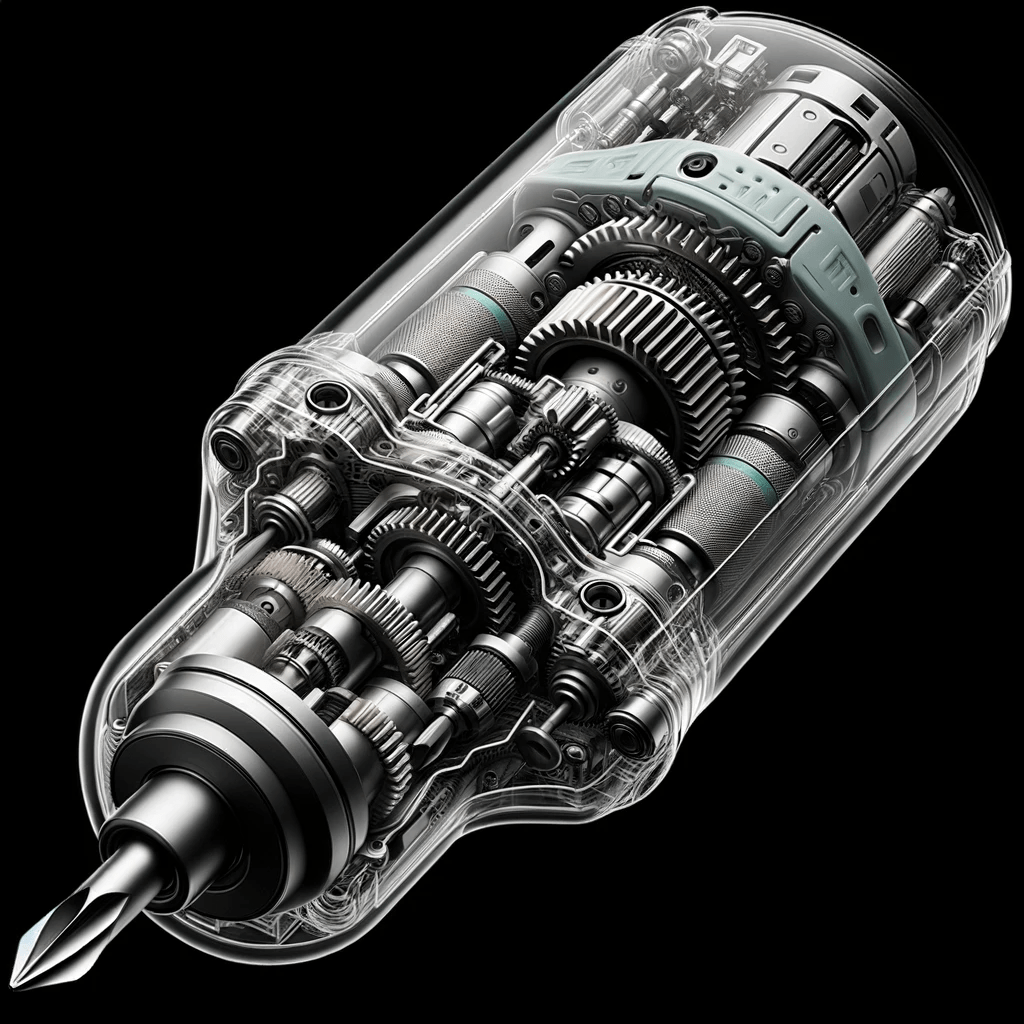

In the age of technological advancement, various powered tools have emerged, offering more efficient and precise screwdriving capabilities. Cordless drills, impact drivers, and electric screwdrivers can significantly expedite tasks.

However, the key is to:

- Choose the right torque setting: Over-torquing can damage the screw or the material.

- Select the correct speed: Higher speeds might be efficient but can lead to stripped screws if not controlled.

- Use quality bits: Invest in high-quality bits that resist wear and offer a snug fit.

4. Key Advanced Screwdriving Techniques

To elevate your screwdriving skills, consider the following advanced techniques:

- Pilot holes: Before inserting larger screws, drill a pilot hole to prevent the material from splitting.

- Counter sinking: This technique involves creating a recessed hole, allowing the screw to sit flush or below the material’s surface.

- Angled screwdriving: For tight spaces or unique angles, learning to drive screws at an angle without compromising their grip is invaluable.

- Using thread lubricants: For woods prone to splitting or metals that might seize, a thread lubricant can ease the screwing process.

- The back-out technique: If a screw gets stuck, slightly reversing it before proceeding can help realign the threads and reduce resistance.

5. Ensuring Safety While Employing Advanced Techniques

Safety is paramount. Always wear safety goggles to protect your eyes from flying debris. When working with hardwood or metal, gloves can offer additional protection against splinters or sharp edges. Furthermore, always ensure your working space is well-lit to clearly see your task and avoid mistakes.

For those looking to enhance efficiency and precision in their projects, a versatile cordless combo kit can make advanced screwdriving tasks much easier.

You may also want to read about how to measure screw sizes, the best subfloor screws and how to remove stripped screws from metal.

Mastering advanced screwdriving techniques not only boosts efficiency but also ensures the longevity and durability of your projects. As the world of fasteners and tools evolves, staying updated with the latest techniques and best practices is crucial for both professionals and enthusiasts. Remember, with the right knowledge, tools, and techniques, you can achieve impeccable results every time.

Note: This article aims to provide comprehensive knowledge on advanced screw-driving techniques. It’s essential to always consult with professionals or trusted sources when unsure about any procedure or technique.

1 Comment