The Unsung Hero of a Great Floor

The most beautiful hardwood, tile, or carpet is only as good as the foundation beneath it. The subfloor is the unsung hero of your home. It’s the invisible structure that provides the strength, stability, and silence you expect from a quality build. When done right, you’ll never think about it again. When done wrong, it will remind you with every squeak, creak, and groan.

As Jody Dedmon of Weyerhaeuser puts it:

“A beautiful floor starts with a stable subfloor.“

The good news is that achieving a professional-quality, silent floor is well within the reach of any dedicated DIY enthusiast. The entire process hinges on understanding and preventing a few common, but critical, installation mistakes. By the end of this guide, you’ll have the knowledge to build a subfloor that will stand strong and silent for generations.

Before we dive into the ‘how-to,’ it’s crucial to understand the ‘why’—what actually causes those annoying floor squeaks in the first place?

1. Understanding the Enemy: What Causes Floor Squeaks?

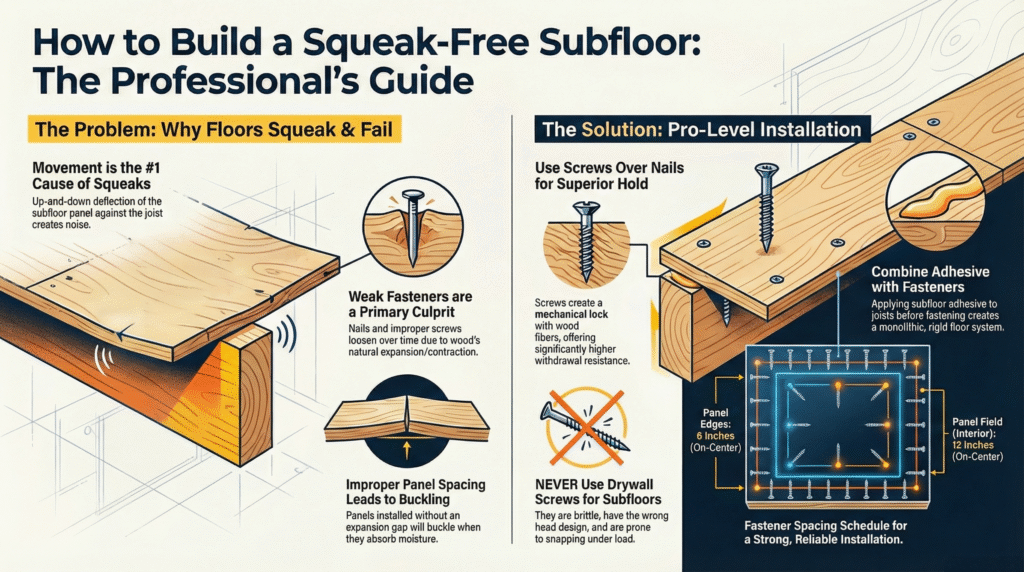

At its core, every single floor squeak comes from one root cause: movement. When a subfloor system isn’t locked together as a single, rigid unit, its components can move independently under the pressure of foot traffic. This movement creates friction, and that friction creates noise. There are two primary types of movement to watch out for:

- Deflection: This is the up-and-down flexing or “bouncing” of a subfloor panel as you walk across it. This happens when the panels are too weak for the span between the floor joists or when the joists themselves are not adequately supported. This bounce allows the subfloor panel to move up and down on the joist or rub against fasteners, creating noise.

- Fastener Movement: This occurs when a subfloor panel rubs against the shank of a nail or screw. It’s often the result of using the wrong fasteners, which can loosen or “pop” over time. This can be caused by the natural shrinking of “green” lumber as it dries or the swelling of subfloor panels that have absorbed moisture, both of which allow the panel to move up and down on the fastener.

Now that you know movement is the true culprit, let’s examine the three most critical installation mistakes that allow this movement to happen and, more importantly, how to prevent them.

2. The “Big Three” Subfloor Mistakes and How to Avoid Them

Mastering these three steps will solve the vast majority of potential subfloor problems. Think of them as the non-negotiable rules for a silent, solid floor.

Mistake #1: Skipping the Subfloor Adhesive

Problem: Relying on fasteners alone is the number one cause of future squeaks. Over time, wood moves and joists can shrink, creating tiny gaps between the subfloor and the framing. This allows for the micro-movements that generate noise. The professional standard and optimal technique is a “glue-nailed” or “glue-screwed” system that creates a single, unified floor structure. As one professional on Reddit stated bluntly:

“I have never seen, or even heard of anyone in the US not using adhesive when installing subfloor.”

Solution:

- Always Use Glue: Subfloor adhesive is not optional. It bonds the panels to the joists, transforming them from separate components into a composite “T-beam structure.” This makes the entire floor system dramatically stronger and stiffer, virtually eliminating the vertical movement that causes squeaks. This isn’t the place to save a few bucks. The right adhesive is the cheapest insurance you’ll ever buy for a silent floor.

- Choose the Right Glue: Use a solvent-based subfloor adhesive that meets ASTM D3498 performance standards. This ensures you’re using a product specifically engineered for the job.

- Apply It Correctly: Apply a continuous ¼-inch bead of adhesive along the top of the floor joists. For wider supports (3½ inches or more), use a serpentine pattern. At the locations where the ends of two panels meet over a joist, apply two beads of glue to ensure both panels get a solid bond.

- Pro Tip: For an absolutely bulletproof installation, run an additional 1/8-inch bead of glue in the groove of each panel before fitting it to the tongue of the previous one. This locks the panels to each other as well as to the joists.

Without glue, you’re building a floor that is guaranteed to develop squeaks as the house settles and the seasons change.

Mistake #2: Improper Fastening

Problem: Even with glue, the right fasteners and a proper fastening pattern are essential. Using the wrong type of nail (like smooth shank nails), the wrong size, or an inconsistent pattern can lead to “nail pops” (where the nail works its way up), “pullouts” (where it loses its grip), and “shiners” (where the nail misses or barely grazes the joist). All of these issues create a point of movement and a potential squeak.

Solution: Pay attention here. A sloppy fastening job, even with glue, is just asking for trouble down the road. This comes down to two key decisions you’ll make on the job.

- First, Choose Your Fastener: The debate between nails and screws is common, but the reality is that both can produce excellent, squeak-free results when used correctly with adhesive.

| Feature | Ring Shank Nails | Subfloor Screws |

| Cost | Less expensive. | Significantly more expensive. |

| Speed | Faster to install, especially with a framing nailer. | Slower to install. |

| Holding Power | Excellent grip (“bite like hell”). Very difficult to pull out. | The best option for eliminating squeaks and preventing pullouts. |

| Best For | Production building, budget-conscious projects. | Custom homes, or any project where eliminating squeaks is the absolute top priority. |

The key takeaway is this: for a squeak-free floor, either method is excellent as long as it is paired with subfloor adhesive.

- Second, Use the Correct Pattern: Follow a consistent and correct fastening schedule.

- Nail/Screw Size: For panels up to 1 inch thick, use 6d ring-shank or screw-shank nails or 8d common nails. (The ‘d’ stands for ‘penny,’ a traditional measure of nail length). For panels thicker than 1 inch, upgrade to 10d nails.

- Spacing: Space fasteners 6 inches apart along all supported panel edges.

- Spacing: Space fasteners 12 inches apart on all the intermediate joists (the “field” of the panel).

- Pro Tip: Look at your panels! Many premium subfloor panels have a handy fastener template printed directly on their surface to guide your work and ensure you hit the joists perfectly every time.

An improper fastening job leaves the door open for fastener movement, which is a primary squeak culprit that even glue can’t always overcome.

Mistake #3: Forgetting the Expansion Gap

Problem: Wood is a natural material that expands and contracts with changes in humidity. If you install subfloor panels tightly against each other, they have no room to expand when the humidity rises. This pressure can cause the panels to push against each other and buckle, creating high spots, unevenness, and noise.

Solution: This is one of the simplest rules to follow, yet one of the most critical.

- The 1/8-Inch Rule: Always leave a 1/8-inch gap at all panel edges and ends. This tiny gap is all the room the panel needs to expand without causing problems. Don’t worry about the gap—it will be covered by your finished flooring. Many modern tongue-and-groove panels (like Weyerhaeuser’s Edge Gold®) are even designed to “self-gap” when the tongue is inserted fully into the groove.

Skipping this gap is one of the most common DIY mistakes. When humidity rises, panels with no room to expand will buckle, creating high spots you can feel underfoot and hear with every step.

Pro-Level Check: Matching Panel Thickness to Joist Spacing

A truly rock-solid floor isn’t just about glue and fasteners; it’s about making sure your subfloor panels are thick enough for the job. The farther apart your joists are, the thicker your subfloor needs to be to prevent that bouncy, trampoline effect. Pros follow specific minimums, and you should too. Here are the industry standards:

- Joist Spacing up to 16 inches: Use a minimum of 19/32″ plywood or 23/32″ OSB.

- Joist Spacing up to 19.2 inches: Use a minimum of 23/32″ plywood or OSB.

- Joist Spacing up to 24 inches: Use a minimum of 7/8″ plywood or OSB.

Beyond the ‘Big Three’ installation steps, the materials you choose and how you handle them are just as critical for a successful project.

3. Mistakes in Material Selection and Handling

A perfect installation can be undermined from the start if you’re using subpar or improperly handled materials. Don’t build your floor on a shifty foundation. It’s that simple.

Mistake #4: Using “Green” or Wet Joists

Problem: “Green” dimensional lumber is wood that has not been properly dried and still has a high moisture content. As this wet lumber dries out in your home, it will shrink, twist, and change shape. This movement is a primary cause of loosened fasteners and, you guessed it, squeaks.

Solution: Start with a stable foundation for your subfloor.

- Use Kiln-Dried Lumber: This lumber has been dried in a controlled environment, making it much more dimensionally stable than green lumber. It’s less prone to shrinking and warping after installation.

- Use Engineered I-Joists: Products like Trus Joist® TJI® joists are manufactured to be perfectly straight and dimensionally stable. They are highly resistant to the shrinking and twisting that plague traditional wet lumber, making them a superior choice for preventing squeaks.

Mistake #5: Not Allowing Panels to Dry

Problem: It’s a reality of construction—sometimes your materials get rained on. When OSB or plywood panels get wet, they can swell, especially at the edges. This “edge swell” creates high ridges at the seams. If you install your finished flooring (especially something sensitive like hardwood) over these swollen, wet panels, you are locking in moisture and creating an uneven surface that will cause major problems down the road.

Solution: A little patience now saves a huge headache later.

- Store Materials Properly: The best cure is prevention. Always store your subfloor panels under cover and off the ground to protect them from the elements.

- Be Patient: If your panels are exposed to significant weather during construction, you must allow them to dry out completely before covering them with finished flooring.

- Consider Premium Panels: High-performance panels like Weyerhaeuser Edge Gold® often include features like patented drainage grooves that help shed standing water, reducing the amount of moisture absorbed and minimizing edge swell.

With the right materials on site, avoiding a few common process errors during installation will keep your project on track.

4. Common Installation Technique Errors

These are the on-the-job mistakes that can compromise all the careful planning you’ve done.

Mistake #6: Rushing the Glue and Letting It “Skin Over”

Problem: Subfloor adhesive works by creating a powerful chemical bond between the panel and the joist. If you apply the glue and leave it exposed to the air for too long before setting the panel, it will begin to cure and form a “skin.” Once this skin forms, the glue loses its bonding strength and will not create the rigid connection you need.

Solution: Think one panel at a time.

- Work in small, manageable sections. Only apply enough adhesive to install one or two panels at a time. Lay your panel immediately and fasten it down completely before moving on to apply glue for the next one.

Mistake #7: Banging Panel Edges with a Sledgehammer

Problem: It can be tempting to force a tight tongue-and-groove joint into place with a few taps from a sledgehammer. Don’t do it. Brute force is the enemy of fine carpentry. This method can crush the wood fibers on the tongue and groove, damaging the panel and creating a weak joint. Even worse, it can accidentally close that critical 1/8-inch expansion gap.

Solution: Use the right technique for persuasion.

- If a panel needs a little help seating into the groove, always use a block of wood as a buffer between your hammer and the panel’s edge. Tapping on the wood block distributes the force and protects the delicate groove edge from being crushed.

After you’ve carefully selected your materials and followed these installation best practices, there is one final step that separates the amateurs from the pros.

5. The Final, Crucial Step: Your Pre-Flight Check

Think of this as your final quality control inspection. It’s the last, and easiest, chance you’ll have to fix any problems.

- Walk the Floor: Before a single piece of hardwood, tile, or carpet is installed, your job isn’t done. The final step is to walk every single square foot of the subfloor. Listen carefully for any squeaks. Look closely for any issues, like “shiners” that missed the joist or any missing fasteners. Fixing a problem now by adding another screw is easy. Trying to fix a squeak from underneath a finished floor is a nightmare.

Your Foundation for Success

Building a subfloor that will last a lifetime without a single squeak isn’t about some secret carpenter’s trick. It’s about following a few fundamental rules with care and precision. If you remember nothing else, burn these four points into your memory:

- Use the “Glue & Fasten” System: This is the golden rule. Never rely on fasteners alone. A proper adhesive turns separate parts into a single, strong, and silent unit.

- Give It Room to Breathe: That 1/8-inch expansion gap around every single panel is not optional. It’s the safety valve that prevents buckling and noise.

- Use Dry, Stable Materials: Start your project right by using kiln-dried or engineered joists and ensuring your subfloor panels are dry before you cover them up.

- Check Your Work: A final walkthrough to find and fix squeaks before the finished floor goes down is the cheapest and most effective insurance you can get for a job well done.

By following these simple but critical rules, you have the power to build a subfloor that is strong, stable, and wonderfully silent. You’re not just laying down wood; you’re building the quiet foundation for your home’s future. Good luck, and build with confidence.

No Comments